Boeing Internship (Summer 2022)

For Summer 2022, I interned at Boeing as a Mechanical Design Engineer in the Payloads Concept Center. I worked on a variety of mechanical design projects, including a persons-of-reduced-mobility lavatory, an emergency exit aisle life vest deployment mechanism, a high lift actuator tolerance stack-up analysis, and an IMU-mounted portable platform assembly.

In accordance with Boeing’s confidentiality policy, I am only able to disclose limited images with minimal detail of projects completed during this internship. Numerical data will be redacted.

Bolt Latch

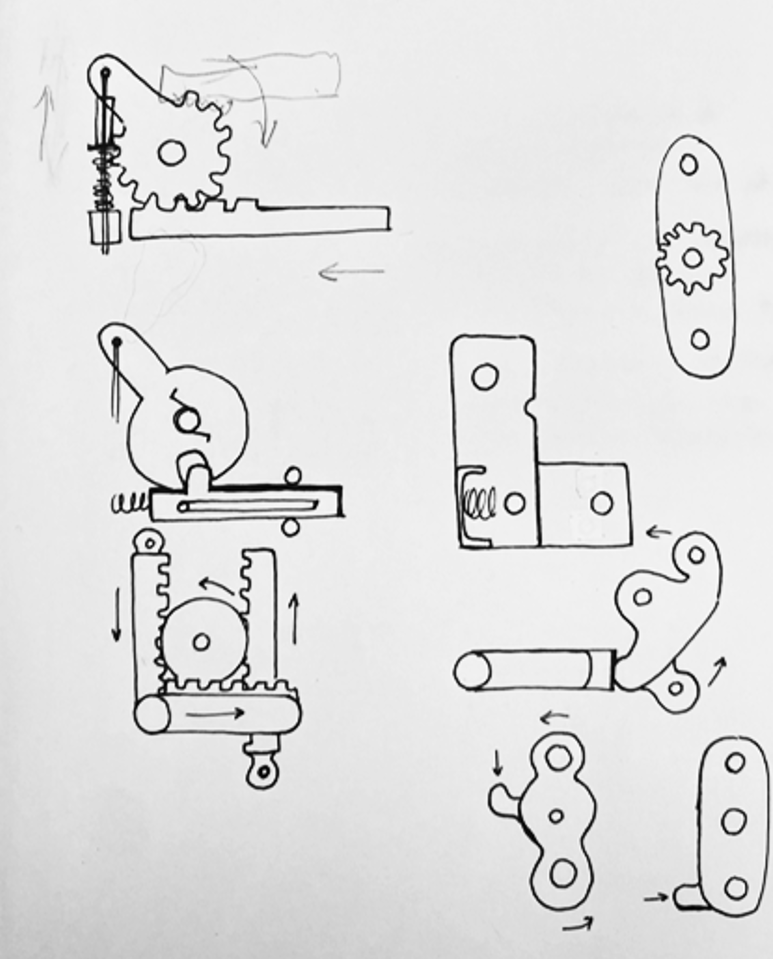

For one of my projects, I needed to design a latch to be actuated from a long distance. I brainstormed a mechanism using an actuating cable and a rack-and-pinion bolt.

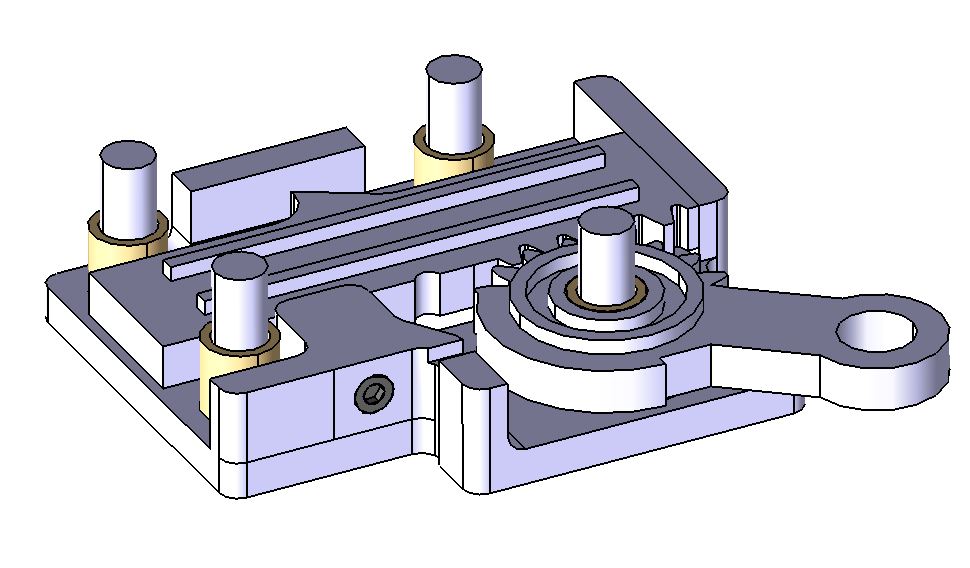

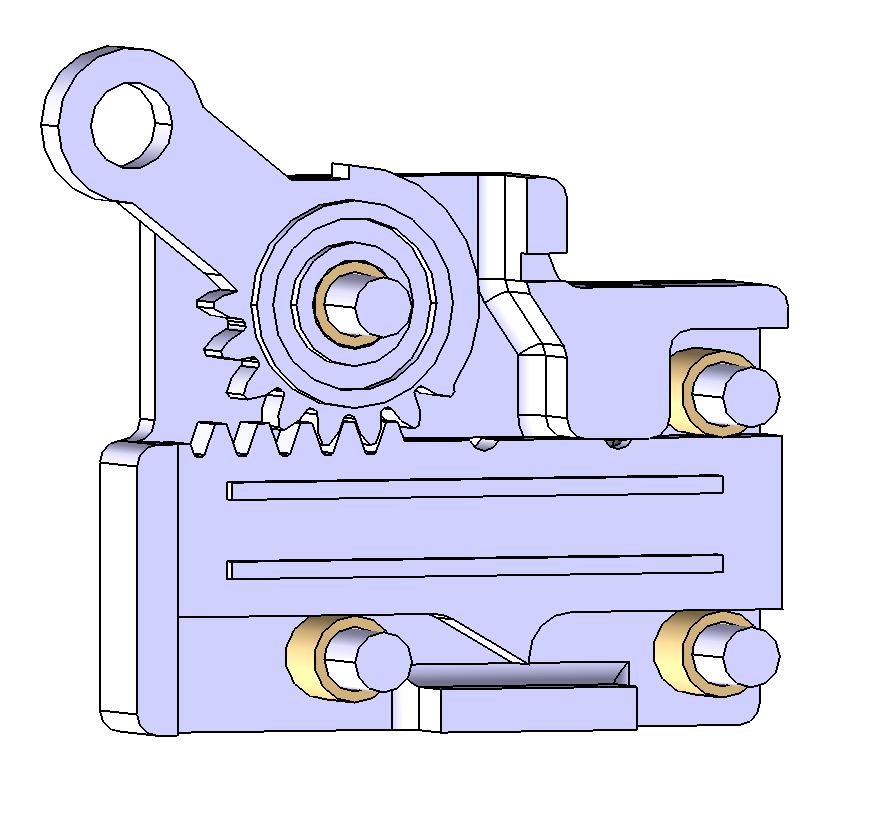

DFM in CATIA V5

My main goal for this project was to design a product for mass production and manufacturing. During the CAD process, I focused on designing features for injection molding with the possibility of modification for stamping. All of the features were designed along the same pull direction, with no concave features requiring undercuts.

I wanted to minimize friction as well as have tactile indents at the minimum and maximum bolt travel. I added bearings and a hex-drive ball detent. For 3D printing, I used clearances of 0.007" on contacting surfaces.

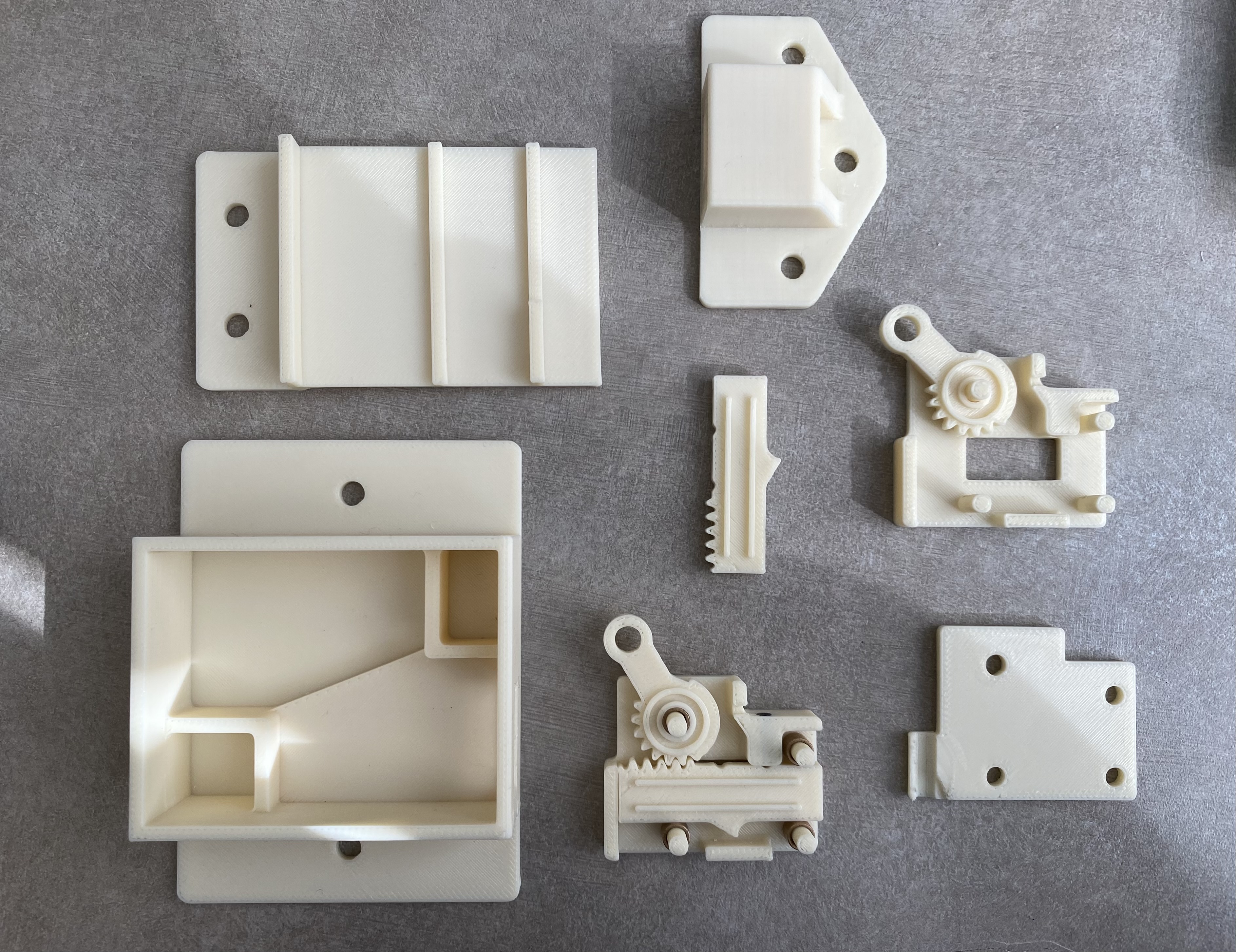

Prototyping

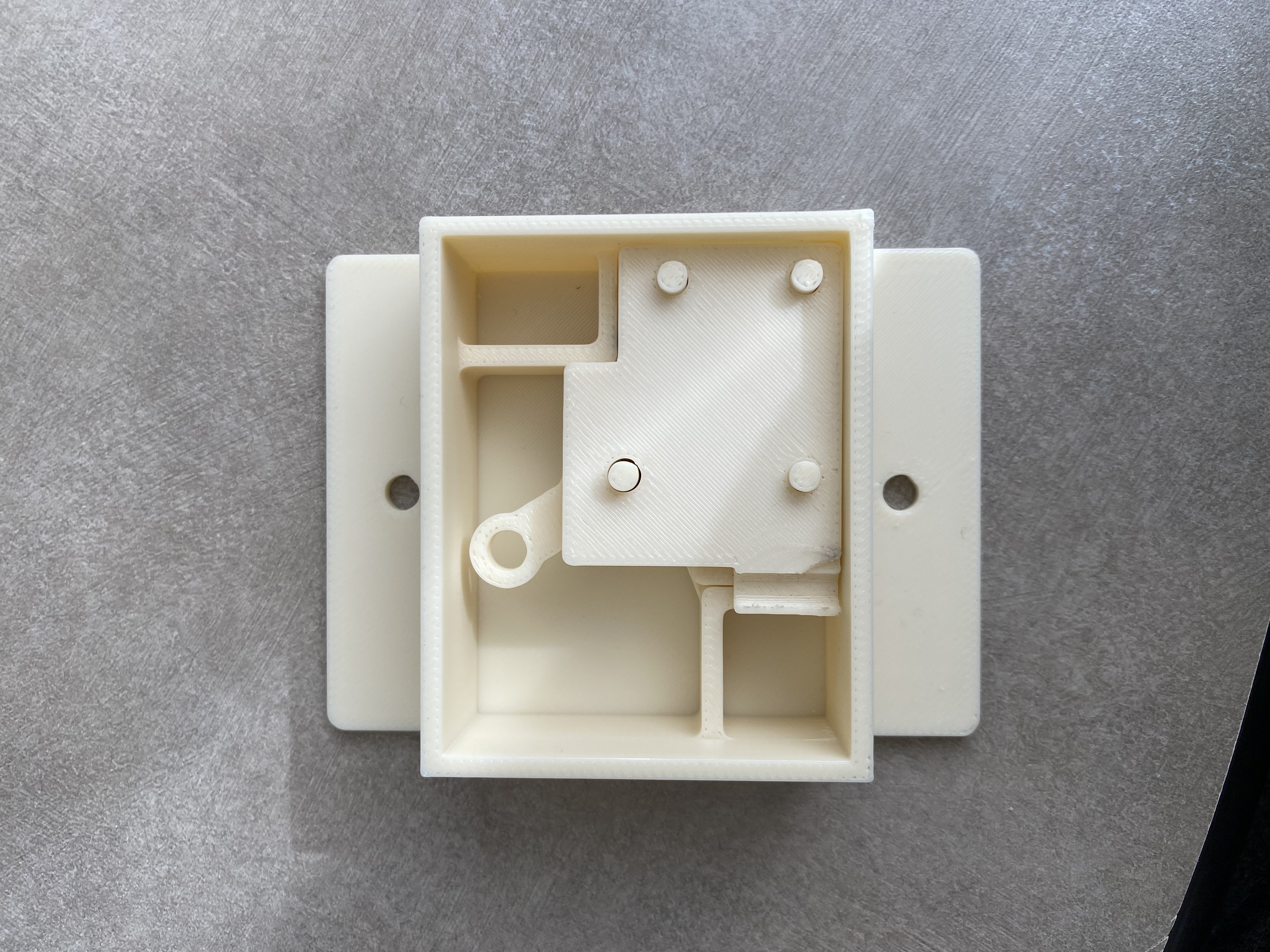

I 3D printed the designs and ordered the parts on McMaster-Carr. Within a day of starting the CAD, I finished assembling the first prototype.

The next day, I designed a housing to mount the bolt latch onto a door. The housing uses the minimum number of features necessary to fully constrain the part, thus minimizing filament material and print time.

Here are some videos of the working latch: